An alfalfa feed pellet machine, also known as a pellet mill or pelletizer, is a specialized piece of equipment designed to process alfalfa and other raw materials into compacted pellets suitable for animal feed. The machine operates through a series of mechanical and thermal processes to transform the raw material into uniform pellets.

Here’s how an alfalfa feed pellet machine works:

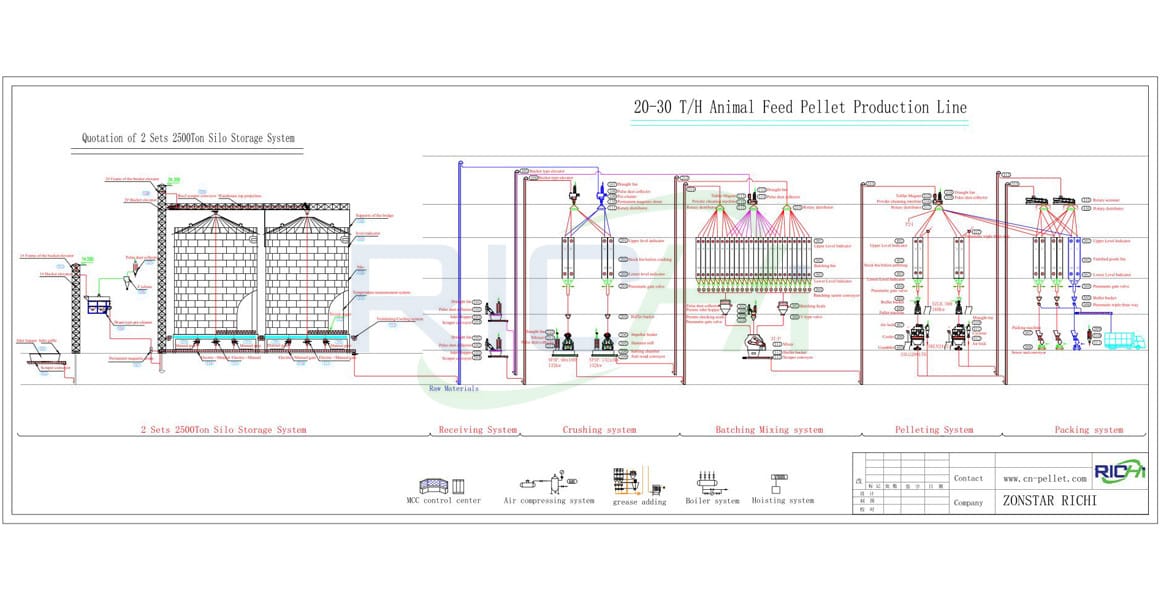

Raw Material Preparation: The process begins with the preparation of the raw material, in this case, alfalfa. The alfalfa is harvested, dried, and often ground or chopped into smaller pieces to facilitate pelletization.

Feeding System: The prepared alfalfa material is then introduced into the pellet machine’s feeding system. This system ensures a consistent flow of material into the pelletizing chamber.

Conditioning: Some pellet machines include a conditioning step, where the alfalfa material may be mixed with water or other additives. This process can help improve the binding properties of the material and enhance pellet quality.

Pelletizing Chamber: The conditioned alfalfa material is fed into the pelletizing chamber. Inside the chamber, the material is subjected to high pressure and heat generated by rollers and a die.

Rollers and Die: The pelletizing chamber contains a set of rollers and a die. The rollers exert pressure on the material as it passes through the die. The die is a metal plate with holes of specific sizes. The pressure and heat soften the alfalfa material, causing it to bind together and form pellets.

Extrusion and Shaping: As the alfalfa material is compressed and pushed through the holes in the die, it undergoes a process called extrusion. This extrusion shapes the material into cylindrical pellets.

Cutting Mechanism: Once the formed pellets emerge from the die, a cutting mechanism (or knife) trims the continuously extruded pellets to the desired length. This ensures uniform pellet size.

Cooling: The freshly cut alfalfa pellets are hot due to the heat generated during pelletization. They are then subjected to a cooling process to reduce their temperature and harden them.

Screening (Optional): Some pellet machines include a screening process to remove fines or undersized pellets, ensuring that the final product is uniform in size.

Collection and Packaging: The cooled and screened alfalfa pellets are collected and can be packaged directly into bags or containers for storage and distribution.

Die and Roller Maintenance: Regular maintenance of the die and rollers is important to ensure consistent pellet quality. Over time, the die and rollers may wear out and need replacement.

The efficiency and quality of an alfalfa feed pellet machine depend on factors such as the design of the machine, the choice of die and rollers, the conditioning process, and the control of pressure and temperature. By carefully adjusting these variables, pellet manufacturers can produce high-quality alfalfa pellets that offer superior nutrition and convenience for animals’ diets.

For more information about alfalfa pellet machine, pls click richi website.