Before planning and designing the automatic control system for the batching and mixing process of the poultry feed pellet making machine, it is necessary to understand the operating characteristics and requirements of the relevant process.

For the current common batch batching and kneading processes of poultry feed machinery, whether it is a multi-silo-weighing-stirring-stirring-stirring system, there are the following common operating characteristics and requirements:

(1) It is a repeated batch operation, each batch of ten simple processes from different raw materials, such as weighing, mixing, mixing, and discharging, are completed in sequence or time.

All kinds of feeding devices, scales, scales, bucket doors, and discharge ports of mixers must move in the specified order or condition. Each poultry feed making machinery and equipment implement the necessary self-locking and interlocking.

(2) The material difference of multiple materials (such as different particle size, bulk density, moisture content, etc.) makes it easy to have different batching accuracy when using the same batching machine to batch different materials.

(3) The formula is often changed or modified due to the need to adapt to the different requirements of feed product users or the stock of raw materials. The system needs to have storage capacity that can store multiple recipes.

(4) Ensure the accuracy of poultry feed pellet making machine ingredients.

(5) Real-time monitoring of the material level of the material warehouse to ensure continued production.

(6) The products in the batching and mixing section can be used as finished products or semi-finished products. The basic data of the production process are important information for the production management, inventory management and raw material management of the entire poultry feed mill factory.

The basic principles of batching design and automatic control of production process are put forward, and the operating process characteristics and requirements of these processing equipment are presented. In planning and design, the requirements of each running process must be considered, so that the system has corresponding control functions.

Because of its practical craftsmanship, excellent quality and excellent service, its products are sold all over the country, and some products have gone to the world and are more and more recognized by the feed industry.

1.What determines the length of feed pellets?

What is the factor of the feed length of the poultry feed pellet making machine? There are many goals to measure the quality of poultry feed pellet making machine, and the discharge length is one of them. Of course, there are many factors related to the discharge length of the poultry feed making machine. Only by fully grasping it can we meet the needs of customers.

Through experimental analysis, the poultry feed pellet making machine manufacturer found that when other parameters of the poultry feed equipment are the same, the higher the output value, the longer the length of the straw pellets, and the length is proportional to the output value.

Poultry feed pellet making machine manufacturers also have a certain relationship with the ring die speed of the feed equipment, and it is still inversely proportional. That is to say, the higher the speed of the ring die, the shorter the feeding length of the feed equipment; on the contrary, the longer the feeding length, the user can adjust the speed according to their needs to meet their respective production needs.

In addition to the above two points, the diameter of the ring die, the number of openings, the density of the raw material and the water content will also affect the discharge length of the straw pellets. Therefore, the raw material should be processed to a moisture content when producing pellets of matter.

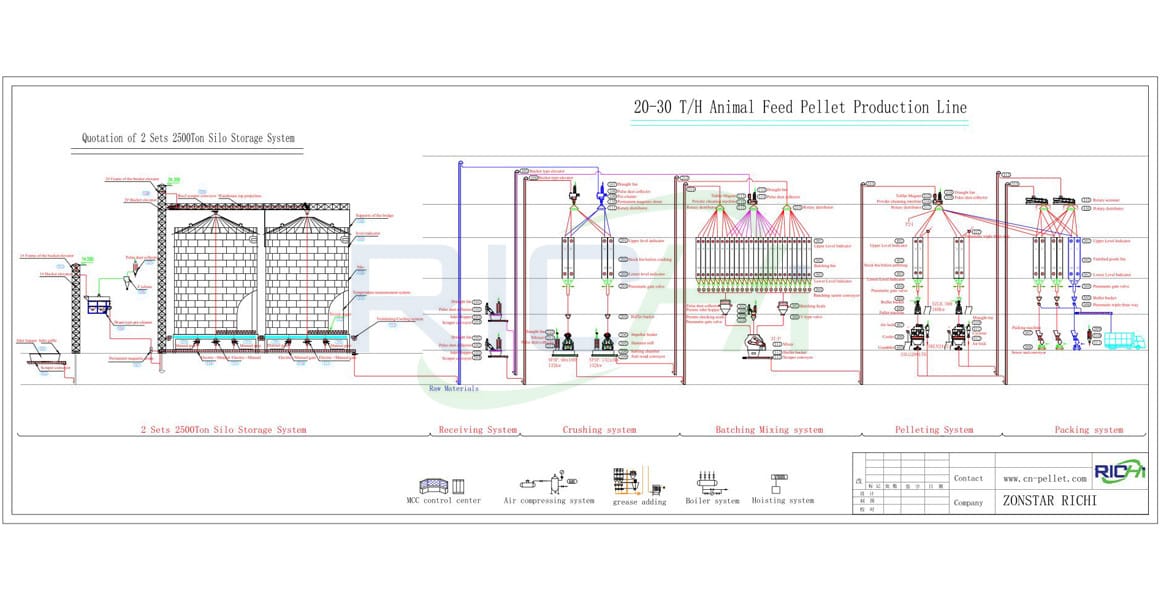

2.What equipment does a complete poultry feed pellet making machine line include?

The poultry feed pellet making machine line generally includes crushing, stirring and pelleting. The main function of the crushing part is to crush and process corn, beans and other particles into powder materials. The equipment includes: single electric crusher, multifunctional hammer crusher, claw crusher, water drop type high-efficiency crusher, large crusher, bean cake crusher, etc. (Related product: hammer mill feed grinder )

The single electric poultry feed pulverizer adopts 220V single electric power, and the hourly output is 100-300 kilograms. The multifunctional hammer crusher is the SFSP model of small and medium feed mills, with a wide range of applications, high efficiency, and large output. The hourly output is generally 800-2000 kg, and the motor is 7.5-15KW.

The crushing principle of the claw crusher is solid, so it can crush smaller materials, but the production efficiency is low, the hourly output is generally 300-800 kg, 5.5-11KW motor.

Large and medium-sized poultry feed mills use large crushers, which have large output and high efficiency, but large energy consumption. The hourly output is 2000-6000 kg, and the motor needs 18.5-37KW. Water drop high-efficiency poultry feed crusher is a new energy-saving product.

The crushing chamber is shaped like a falling water drop. Large screen angle, high production efficiency. The same output can save 10-20% energy than other crushers. The bean cake crusher is a special poultry fed grinder machine for crushing bean cakes. It can crush bean cakes with a diameter of φ600mm and an hourly output of 1000-5000 kg. (For more: Richi Pellet Machine)