Wood pellet processing plants are specialized facilities designed to convert raw wood materials into wood pellets, which are a renewable and sustainable source of energy. These plants play a critical role in the bioenergy sector by providing a means to utilize wood waste and other biomass materials for energy production. This article will explain what a wood pellet processing plant is, its advantages and necessity, the specific processes involved, the importance of choosing the right manufacturer, and a detailed introduction to RICHI Machinery, a leading manufacturer in the industry.

What is a Wood Pellet Processing Plant?

A wood pellet processing plant is a facility where raw wood materials, such as sawdust, wood chips, and forestry residues, are processed and compressed into small, cylindrical pellets. These wood pellets are used as fuel in various applications, including residential heating, industrial boilers, and power plants. The plant typically includes several machines and systems that work together to grind, dry, pelletize, cool, and package the wood materials.

Advantages and Necessity of Wood Pellet Processing Plants

Wood pellet processing plants offer several advantages, making them an essential part of the renewable energy landscape:

- Sustainable Energy Source: Wood pellets are a renewable energy source, derived from waste wood and other biomass materials. This helps reduce dependence on fossil fuels and contributes to carbon neutrality.

- Efficient Waste Management: These plants provide a valuable solution for managing wood waste, converting it into a useful product instead of letting it go to waste in landfills.

- Economic Benefits: Wood pellet production can create jobs in rural areas, stimulate local economies, and provide a profitable use for otherwise low-value wood materials.

- Stable Energy Supply: Wood pellets offer a stable and reliable energy supply, as they can be stored and transported easily, unlike other renewable energy sources such as wind or solar power.

- Environmental Impact: The use of wood pellets reduces greenhouse gas emissions, as they produce less CO2 compared to fossil fuels. Additionally, they help mitigate the effects of deforestation by utilizing wood waste rather than cutting down trees.

Specific Processes Included in a Wood Pellet Processing Plant

A wood pellet processing plant involves several critical steps, each of which contributes to the final product’s quality. These processes include:

- Raw Material Preparation

- Grinding: The raw wood materials are ground into fine particles using a hammer mill or grinder. This step is crucial for creating a uniform particle size that can be easily pelletized.

- Drying

- Moisture Reduction: The ground wood particles are then dried to reduce their moisture content. Ideal moisture content is usually between 10-12%. Proper drying is essential for producing high-quality pellets.

- Pelletizing

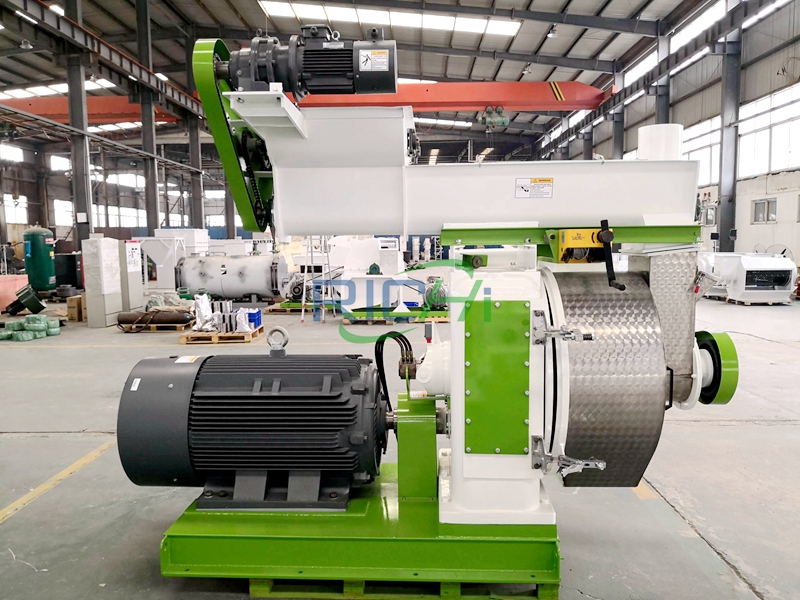

- Compression and Formation: The dried wood particles are compressed and extruded through wood pellet machines for sale die to form cylindrical pellets. The pelletizing process is the core of the plant and requires precise control to ensure consistent pellet quality.

- Cooling

- Pellet Stabilization: The freshly formed pellets are hot and soft, so they are cooled to harden and stabilize them. Cooling also reduces the moisture content further, which is important for storage.

- Screening

- Quality Control: The pellets are screened to remove any fines or broken pieces, ensuring only high-quality pellets are packaged.

- Packaging

- Storage and Distribution: The final step is packaging the pellets into bags or bulk containers for distribution. Proper packaging helps protect the pellets from moisture and contamination during storage and transport.

The Most Important Process: Pelletizing

While each process in a wood pellet processing plant is essential, the pelletizing stage is the most critical. This is where the raw materials are transformed into the final product, and the quality of the pellets depends heavily on the precision and efficiency of this process. Key factors to pay attention to during pelletizing include:

- Die and Roller Design: The design of the pellet mill die and rollers affects the compression and extrusion process. High-quality dies and rollers ensure consistent pellet size and durability.

- Temperature Control: Maintaining the right temperature during pelletizing is crucial for binding the wood particles together without burning them.

- Feed Rate: The rate at which raw materials are fed into the pellet mill must be carefully controlled to prevent overloading and ensure uniform pellet production.

Choosing the Right Output for Your Needs

The output capacity of a wood pellet processing plant is typically measured in tons per hour (TPH). The appropriate capacity depends on the scale of your operation and your specific needs:

- Small-Scale Production: For small businesses or farms, a plant with an output of 0.5 to 1 TPH may be sufficient.

- Medium-Scale Production: Medium-sized operations might require a plant with an output of 2 to 5 TPH.

- Large-Scale Production: For industrial or large commercial operations, a plant with an output of 10 TPH or more might be necessary.

To calculate the required output, consider factors such as the amount of raw material available, the intended use of the pellets, and the expected demand. For example, if you have access to a large amount of wood waste and a steady demand for pellets, a higher output capacity may be necessary to meet production goals.

Importance of Choosing a Manufacturer

Selecting the right manufacturer for your wood pellet processing plant is crucial to ensuring you receive a reliable, high-quality machine that meets your production needs. When choosing a manufacturer, consider the following factors:

- Experience and Reputation: A manufacturer with a strong track record and positive customer feedback is more likely to provide reliable and durable equipment.

- Technical Support: Ensure the manufacturer offers comprehensive technical support, including installation, training, and maintenance services.

- Customization Options: Some manufacturers offer customization options to tailor the plant to your specific needs, which can be beneficial for optimizing production.

- Certifications and Compliance: Check that the manufacturer’s equipment complies with industry standards and has the necessary certifications, such as ISO and CE.

Introduction to RICHI Machinery

RICHI Machinery is recognized as the most professional pellet mill manufacturer in China and the largest pellet mill manufacturer in Henan, China. With years of experience in the industry, RICHI Machinery has established itself as a leader in the production of high-quality pellet processing equipment.

Professionalism and Market Position

RICHI Machinery’s professionalism is evident in its commitment to quality, innovation, and customer satisfaction. The company has a dedicated team of engineers and technicians who continuously work on improving their products and developing new technologies. This focus on innovation has allowed RICHI to maintain a strong position in the global market, with a reputation for producing reliable, efficient, and durable pellet mills.

Turnkey Solutions and Customer Support

RICHI Machinery offers comprehensive turnkey solutions, handling everything from design and manufacturing to installation and training. This all-in-one service is particularly valuable for customers who require a fully integrated pellet production line. In addition, RICHI provides excellent after-sales support, ensuring that customers receive prompt assistance with any technical issues.

Conclusion

A wood pellet processing plant is a vital component in the production of renewable energy, offering numerous environmental and economic benefits. Understanding the specific processes involved and the importance of each step, especially pelletizing, is key to optimizing production. When choosing a plant, it’s crucial to consider your output needs and select a reputable manufacturer like RICHI Machinery. With their expertise, innovative technology, and comprehensive support, RICHI Machinery is a top choice for anyone looking to invest in a high-quality wood pellet processing plant.