Indonesia has a rapidly developing livestock industry, with growing demand for beef and dairy products driven by population growth and changing dietary habits. As cattle, sheep, and goat farming continues to modernize, the ruminant feed production line in Indonesia has become a vital solution for feed manufacturers and large-scale farms seeking stable feed quality, efficient production, and cost control.

Indonesia’s Ruminant Farming Landscape and Feed Resources

Ruminant farming in Indonesia relies on a wide range of locally available raw materials. Common feed ingredients include natural grasses, palm fiber, corn, rice bran, cassava residue, coconut by-products, and soybean meal. These materials provide a solid foundation for ruminant feed manufacturing in Indonesia, allowing producers to formulate both roughage-based and concentrate feeds.

With limited pasture land in certain regions, pelletized ruminant feed plays an increasingly important role. A professional ruminant feed pellet production line in Indonesia helps improve feed utilization efficiency, reduce storage losses, and ensure balanced nutrition across different growth stages.

Standard Process Flow of a Ruminant Feed Production Line

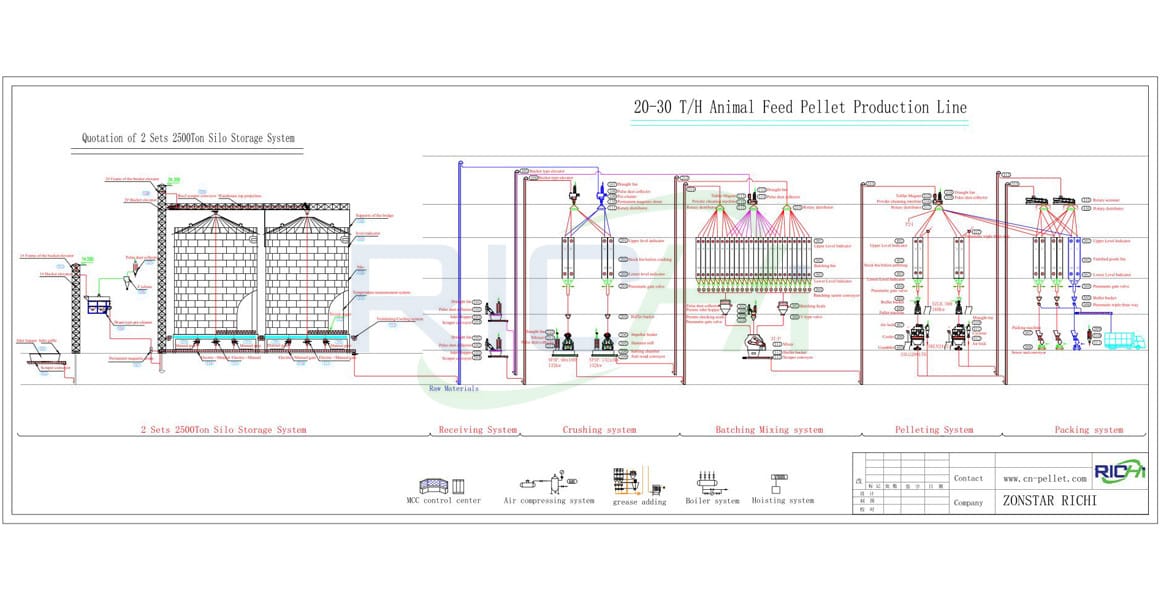

A modern ruminant feed production line in Indonesia is typically composed of several integrated processing systems designed to handle high-fiber raw materials efficiently.

The process begins with raw material cleaning and pre-treatment, where impurities such as stones and metal are removed to protect equipment. Next, the grinding system reduces grains and fibrous materials to suitable particle sizes, ensuring better mixing and digestibility.

The batching and mixing section accurately weighs and blends multiple ingredients, vitamins, and minerals according to feed formulations. This step is critical for producing nutritionally consistent feed. The mixed material then enters the pelleting section, where a heavy-duty livestock feed pellet machine compresses the feed into uniform pellets suitable for cattle, sheep, and goats.

After pelleting, the hot feed pellets are cooled in a counterflow cooler to enhance hardness and storage stability. Screening systems remove fines, and the final products are packed in bags or stored in silos, ready for transportation and on-farm use.

(browse around this web-site: https://pelletisingmachine.com/animal-feed-production-line/)

Key Technical Advantages for Indonesian Conditions

A well-engineered ruminant feed production line in Indonesia is designed to cope with high-fiber materials such as grass meal and palm fiber. Wear-resistant ring dies and rollers ensure long service life and stable output under continuous operation.

High automation levels allow precise control over production parameters, minimizing human error and reducing labor costs. An automatic ruminant feed production line in Indonesia improves production efficiency while maintaining consistent pellet quality.

In addition, modular design enables flexible capacity expansion, making the system suitable for small and medium feed mills as well as large commercial operations.

Applications Across Different Ruminant Species

A professionally configured ruminant feed processing line in Indonesia can produce feed pellets for beef cattle, dairy cattle, sheep, and goats. By adjusting formulations and pellet specifications, producers can supply feed tailored to calves, growing animals, and finishing stages.

Pelletized ruminant feed improves feed intake, reduces selective feeding, and supports better animal performance. This makes ruminant feed pellet production in Indonesia an essential component of modern livestock management.

Economic and Sustainability Benefits

Investing in ruminant feed production equipment in Indonesia offers long-term economic benefits. On-site feed production reduces dependence on external suppliers, lowers feed costs, and enhances quality control.

From a sustainability perspective, utilizing local agricultural by-products in ruminant feed supports waste reduction and promotes circular agriculture. Efficient feed production also contributes to improved feed conversion ratios and reduced environmental impact.

(view it)

Conclusion

With abundant feed resources and growing demand for livestock products, Indonesia presents strong opportunities for modern ruminant feed production. A reliable ruminant feed production line in Indonesia enables efficient processing of local raw materials into high-quality feed pellets, supporting productivity, profitability, and sustainable growth in the livestock sector.