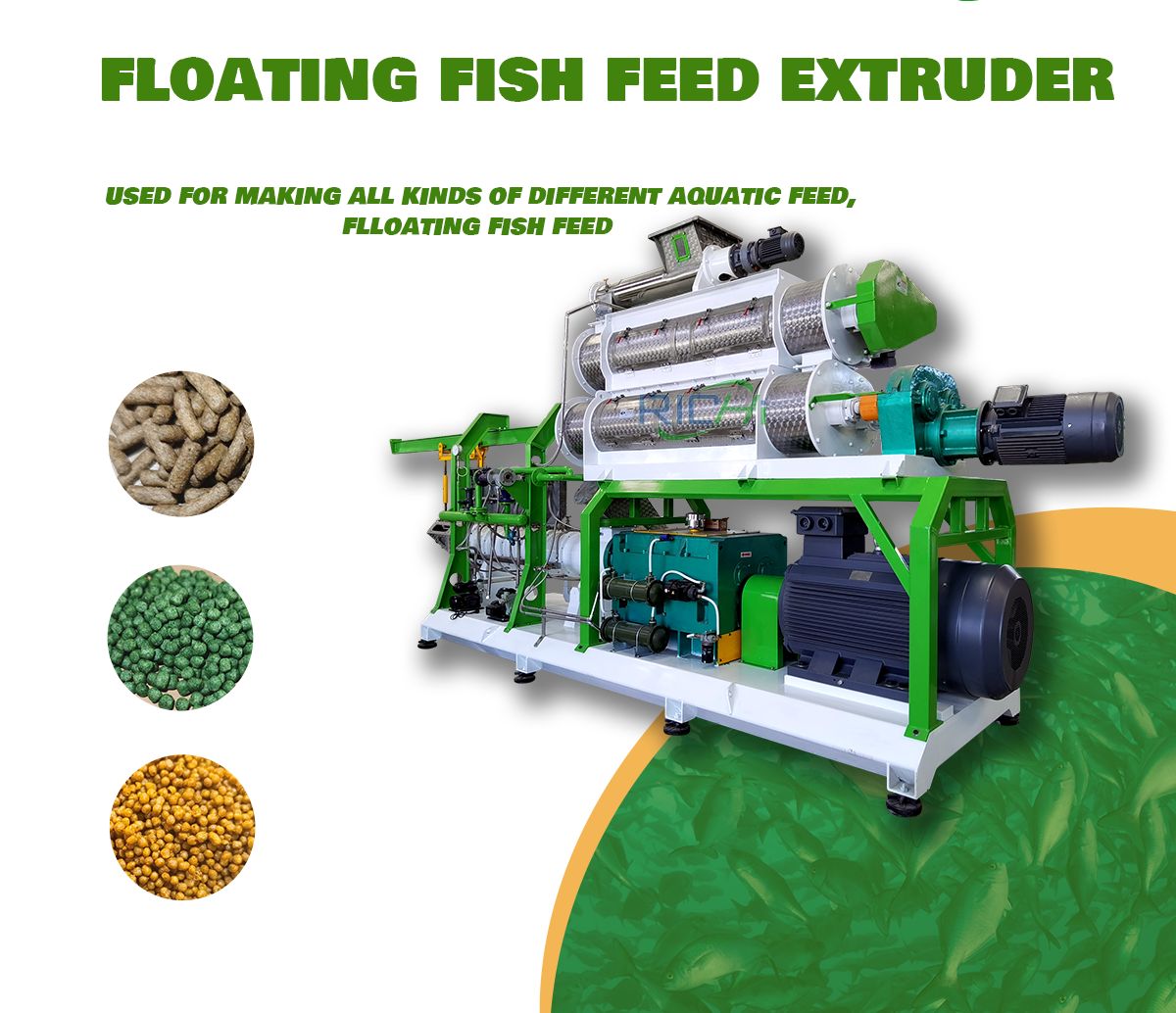

The current fish floating feed machine products have become more and more advanced with the advancement of science and technology. Now the new type of twin-screw floating fish feed extruder machine has developed relatively late in China. After such mechanical materials are sent to the conditioner by the conveying equipment, the materials are conditioned and tempered.

After being quenched and tempered by high-temperature steam in the fish floating feed machine device, it enters the puffing mechanism from the discharge trough, and is instantly extruded and cut into granules from a certain shape of the die hole under the pumping of a pair of mutually parallel and meshing screws. (Related post: floating fish feed making machine)

Due to the wide range of extruded raw material characteristics, the screw speed needs to be adjusted within a large range. Its working principle is much more complicated than that of a single-screw fish floating feed machine, and there are large differences in specific structures, especially the barrel, screw.

The arrangement of the thrust bearing gearbox is more complicated, resulting in an increase in equipment cost. For example, the single-screw adopts a belt for primary transmission, while the twin-screw fish floating feed machine adopts a gearbox for transmission. The two have great differences in manufacturing and transmission efficiency.

1. Working principle of fish floating feed machine

The working principle of the floating fish feed making machine is actually relatively simple. As we mentioned in the overview of the floating fish feed extruder, the floating fish feed pellet mill uses mechanical energy to convert thermal energy to provide kinetic energy.

Usually the extrusion propulsion of the fish floating feed machine’s non-equidistant non-standard screw system, the gas in the material is discharged and quickly filled with the material.

The material is backflowed by the shear force, which increases the pressure in the fish floating feed machine chamber. At the same time, the mechanical energy is converted into heat energy through the friction of the material in the chamber, so that the material It becomes a gel state with flowing properties.

When the material is squeezed to the outlet, the pressure changes from high pressure to normal pressure instantaneously, and from high temperature to normal temperature instantaneously, resulting in the rapid evaporation of water from the tissue structure.

The friction between the materials fully mixes, squeezes, heats, glues, and gelatinizes the material to produce tissue changes. The original structure of the fish floating feed machine is destroyed, and countless microporous structures are formed inside. Then, through the cutting device, the puffed food is formed after cutting and cooling. (Related post:animal feed mill plant)

2. Main use of fish floating feed machine

The main purpose of the fish floating feed machine extruder is self-evident. The main function of all fish floating feed machines is to puff up food. It can make the food larger and looser after processing. The main purpose of the puffing machine is to puff up the food.

The puffing in the extrusion cavity is actually a high temperature and instantaneous process, which plays a very good role in the processing of food raw materials. The state of “popcorn” not only changes its physical state, but also changes its internal organic molecular structure, making the starch easier to digest and the protein easier to use. (Related post:twin screw extruder for sale)

Compared with ordinary full-price granular foods, puffed food made by floating fish feed pellet machine have its unique advantages.

- The palatability of food is improved. After the food raw materials are puffed, the aroma is increased, the palatability is improved, and the appetite of animals can be stimulated.

- The digestibility of food is improved. After the food is puffed, the degree of changing the long-chain structure of protein, fat and other organic matter into short-chain structure increases, so it becomes more digestible.

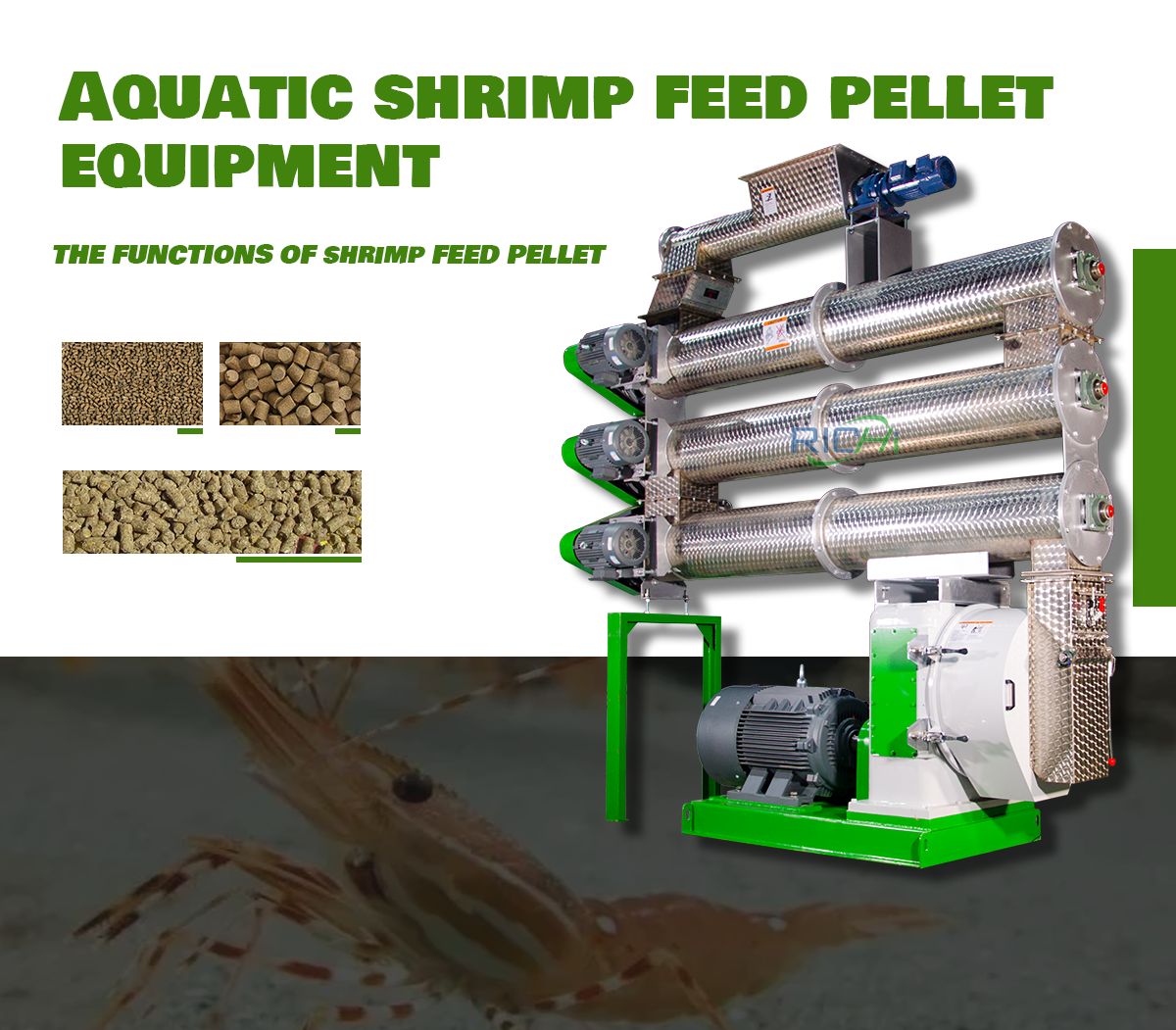

3. Performance characteristics of fish floating feed machine

- Efficient first-stage gear transmission to ensure the transfer of energy;

- All stainless steel feeder, variable pitch anti-arching mechanism, adopt imported frequency conversion speed control;

- Enlarged stainless steel conditioner, which adopts axial inlet steam, greatly improves the time and effect of fish floating feed machine conditioning and curing;

- The high-precision transmission gear and gear shaft are carburized and quenched, and the hard tooth surface is ground, which has stable transmission, low noise and long service life;

- The material of the gear box and the high precision of the transmission hole are guaranteed by the casting technology and CNC machining equipment of the professional foundry;

- The main drive system bearings and oil seals are imported. And a special lubrication oil return system of fish floating feed machine is set up to ensure reliable bearing lubrication;

- The connection between the ring die and the drive wheel adopts three-piece quick-release precision casting hoop, which is convenient and quick to disassemble the fish floating feed machine ring die.