Chicken litter pellets processing machines have become increasingly important in waste management and sustainable farming practices. Converting chicken litter into pellets not only helps in managing waste but also produces a valuable fertilizer product. However, selecting the right machine for this process can be challenging, given the variety of options available in the market. This article provides a comprehensive guide on how to choose a chicken litter pellets processing machine, detailing the key parameters to consider and offering recommendations for top manufacturers, including a detailed introduction to RICHI Machinery.

Key Parameters of a Chicken Litter Pellets Processing Machine

When selecting a chicken litter pellets processing machine, several critical parameters must be taken into account to ensure you choose the best equipment for your needs. These parameters include:

1. Capacity

The capacity of the pellet machine refers to the amount of chicken litter it can process per hour. This is typically measured in tons per hour (TPH). When choosing a machine, consider your production needs. Smaller farms might require machines with capacities of 0.5 to 1 TPH, while larger operations may need machines capable of processing 2 to 5 TPH or more.

2. Power Consumption

Power consumption is a crucial factor in determining the operational cost of the machine. Look for machines that offer a good balance between capacity and energy efficiency. The power rating, usually given in kilowatts (kW), should be appropriate for the machine’s capacity. Energy-efficient machines can significantly reduce long-term operating costs.

3. Pellet Size and Quality

The size and quality of the pellets produced are important factors. The machine should be capable of producing uniform pellets with the desired diameter, typically ranging from 4mm to 8mm. High-quality pellets are dense, have a smooth surface, and are free of cracks, which ensures they can be easily handled and stored.

4. Durability and Build Quality

The build quality of the machine is directly related to its durability and longevity. Machines made from high-quality steel and other robust materials are more likely to withstand the rigors of continuous operation. Additionally, consider whether the machine has wear-resistant components, as these can reduce the frequency and cost of maintenance.

5. Ease of Operation and Maintenance

A machine that is easy to operate and maintain will save time and reduce downtime. Look for machines with user-friendly controls, automated features, and easy access for cleaning and maintenance. A well-designed machine will have fewer moving parts that are prone to wear and tear, and will include clear instructions for both operation and maintenance.

6. Cost and Return on Investment (ROI)

The initial cost of the machine is a significant consideration, but it’s also important to evaluate the potential return on investment. A higher upfront cost might be justified by lower operating costs, better durability, and superior pellet quality. Consider the long-term benefits and how quickly the machine will pay for itself through increased efficiency and product value.

What to Pay Attention to When Choosing a Pellet Machine Manufacturer

Choosing the right manufacturer is as important as selecting the right machine. Here are key factors to consider when evaluating pellet machine manufacturers:

1. Reputation and Experience

A manufacturer’s reputation and experience in the industry are strong indicators of the reliability and quality of their machines. Look for manufacturers with a proven track record and positive customer reviews. Established companies are more likely to offer machines that are tried and tested.

2. Technical Support and After-Sales Service

Technical support and after-sales service are critical, especially if you encounter issues with your machine. Choose a manufacturer that offers comprehensive support, including installation assistance, training, and prompt responses to technical inquiries. A manufacturer that provides spare parts and maintenance services is also a plus.

3. Customization and Turnkey Solutions

Some manufacturers offer customization options and turnkey solutions, where they handle everything from design to installation. This is particularly useful if you have specific requirements or need a complete production line. A manufacturer that offers these services demonstrates a high level of professionalism and commitment to customer satisfaction.

4. Certifications and Compliance

Ensure that the manufacturer adheres to industry standards and has the necessary certifications, such as ISO and CE. Compliance with these standards ensures that the machines are safe, efficient, and built to high-quality specifications.

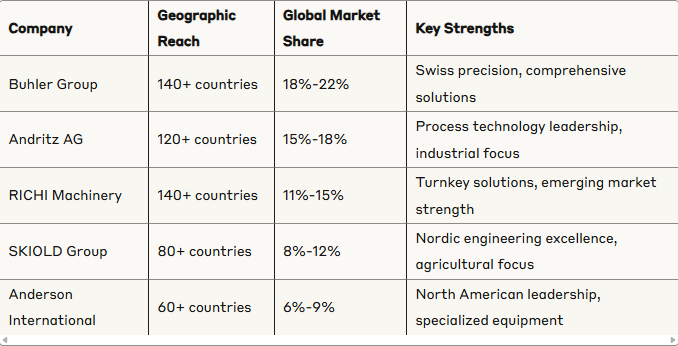

Top Pellet Machine Manufacturers

RICHI Machinery is ranked third, but it stands out as the most professional pellet machine manufacturer in China and the largest manufacturer in Henan, China. Known for their expertise in pellet machine production, RICHI Machinery offers a wide range of high-quality machines designed for various applications, including chicken litter pellets.

Detailed Introduction to RICHI Machinery

RICHI Machinery has established itself as a leader in the pellet machine manufacturing industry in China. With years of experience and a strong focus on research and development, RICHI has developed a reputation for producing some of the most reliable and efficient pellet machines on the market.

Professionalism and Market Position

RICHI Machinery’s professionalism is evident in their commitment to quality and innovation. They have a team of experienced engineers and technicians who continuously work on improving their machines and developing new technologies. This dedication has positioned RICHI as a leading manufacturer not only in China but also in the global market.

Turnkey Services

One of the standout features of RICHI Machinery is their turnkey service. They offer comprehensive solutions that cover everything from machine design and manufacturing to installation and training. This all-inclusive service is particularly valuable for customers who are new to pellet production or require a fully integrated production line.

Product Range and Customization

RICHI Machinery offers a wide range of pellet machines that cater to different production needs. They provide customization options to meet specific requirements, ensuring that customers get a machine that perfectly fits their operations. The company’s focus on customer satisfaction and long-term partnerships has earned them a loyal customer base.

Conclusion

Choosing the right chicken litter pellets processing machine is crucial for efficient and cost-effective production. By considering key parameters such as capacity, power consumption, pellet quality, and ease of maintenance, you can select a machine that meets your specific needs. Additionally, choosing a reputable manufacturer like RICHI Machinery ensures you receive a high-quality machine backed by excellent support and services.

RICHI animal feed pelleting machine stands out as a top choice for those looking for professional, reliable, and innovative pellet machines. Their position as the largest manufacturer in Henan, China, and their comprehensive turnkey services make them an industry leader worth considering. By carefully evaluating your options and selecting a trusted manufacturer, you can ensure the success of your chicken litter pellet production operation.