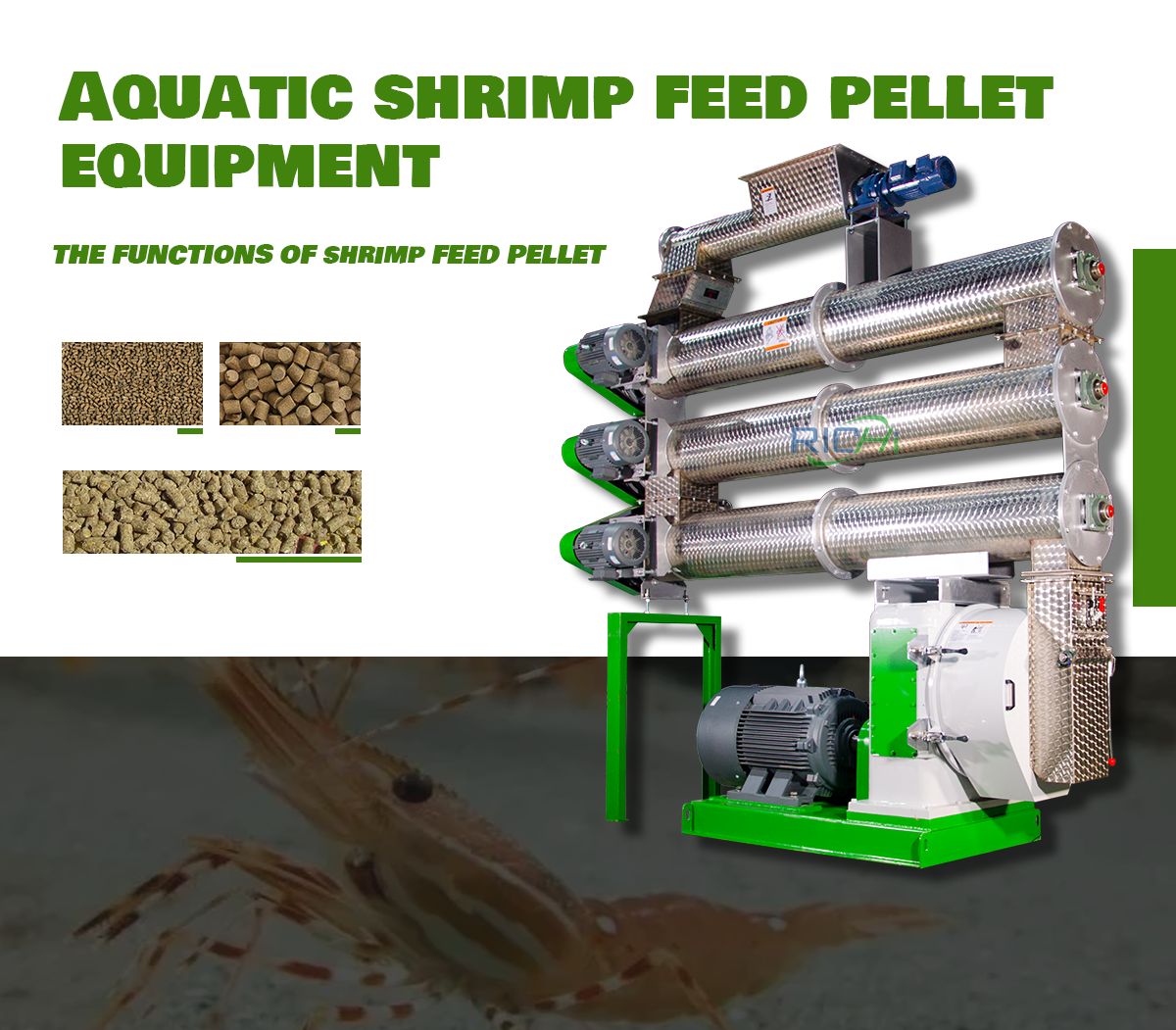

Shrimp farming has become an increasingly important sector in the global aquaculture industry, with demand for shrimp continuing to rise worldwide. As the industry grows, the need for efficient and high-quality feed production has become paramount.

Shrimp feed pellet machines play a crucial role in this context, offering significant benefits to shrimp farmers and feed manufacturers alike. This article explores the importance of shrimp feed pellet machines in modern shrimp farming operations.

Enhancing Feed Quality and Consistency

One of the primary advantages of using shrimp feed pellet machines is the ability to produce high-quality, consistent feed. These machines allow for precise control over ingredient mixing, pellet size, and density, ensuring that each batch of feed meets the exact nutritional requirements of the shrimp at different growth stages. This consistency is crucial for optimal shrimp growth and health, as it helps maintain stable water quality and reduces the risk of disease outbreaks.

Improved Feed Conversion Ratio

Shrimp feed pellet machines can significantly improve the feed conversion ratio (FCR) in shrimp farming. By producing pellets with the right size, density, and nutritional profile, these machines ensure that shrimp can easily consume and digest the feed. This leads to better nutrient absorption and less waste, ultimately resulting in faster growth rates and improved overall farm productivity. (Related post: Shrimp Feed Mill)

Water Stability and Reduced Environmental Impact

One of the critical aspects of shrimp feed is its ability to remain stable in water for an extended period. Shrimp feed pellet machines can produce pellets with excellent water stability, which is essential for several reasons:

- It allows shrimp sufficient time to consume the feed before it disintegrates.

- It reduces nutrient leaching into the water, maintaining better water quality.

- It minimizes feed waste, which can lead to water pollution and increased production costs.

By producing water-stable pellets, these machines contribute to more sustainable shrimp farming practices and help reduce the environmental impact of aquaculture operations.

Cost-Effectiveness and Efficiency

Investing in a shrimp feed pellet machine can lead to significant cost savings for shrimp farmers and feed manufacturers. These machines enable:

- In-house feed production, reducing reliance on expensive commercial feeds.

- Bulk purchasing of raw ingredients, lowering overall feed costs.

- Efficient production processes, minimizing labor and energy expenses.

- Reduced feed waste due to improved pellet quality and water stability.

Over time, these factors contribute to improved profitability and competitiveness in the shrimp farming industry.

Customization and Flexibility

Shrimp feed pellet machines offer a high degree of customization and flexibility in feed production. Farmers and feed manufacturers can:

- Adjust pellet size to suit different shrimp growth stages.

- Modify feed formulations to address specific nutritional needs or health concerns.

- Incorporate additives, probiotics, or medications directly into the feed.

- Produce different types of feed (e.g., starter, grower, finisher) using the same equipment.

This flexibility allows for rapid adaptation to changing market demands or farm conditions, giving producers a competitive edge.

Technological Advancements

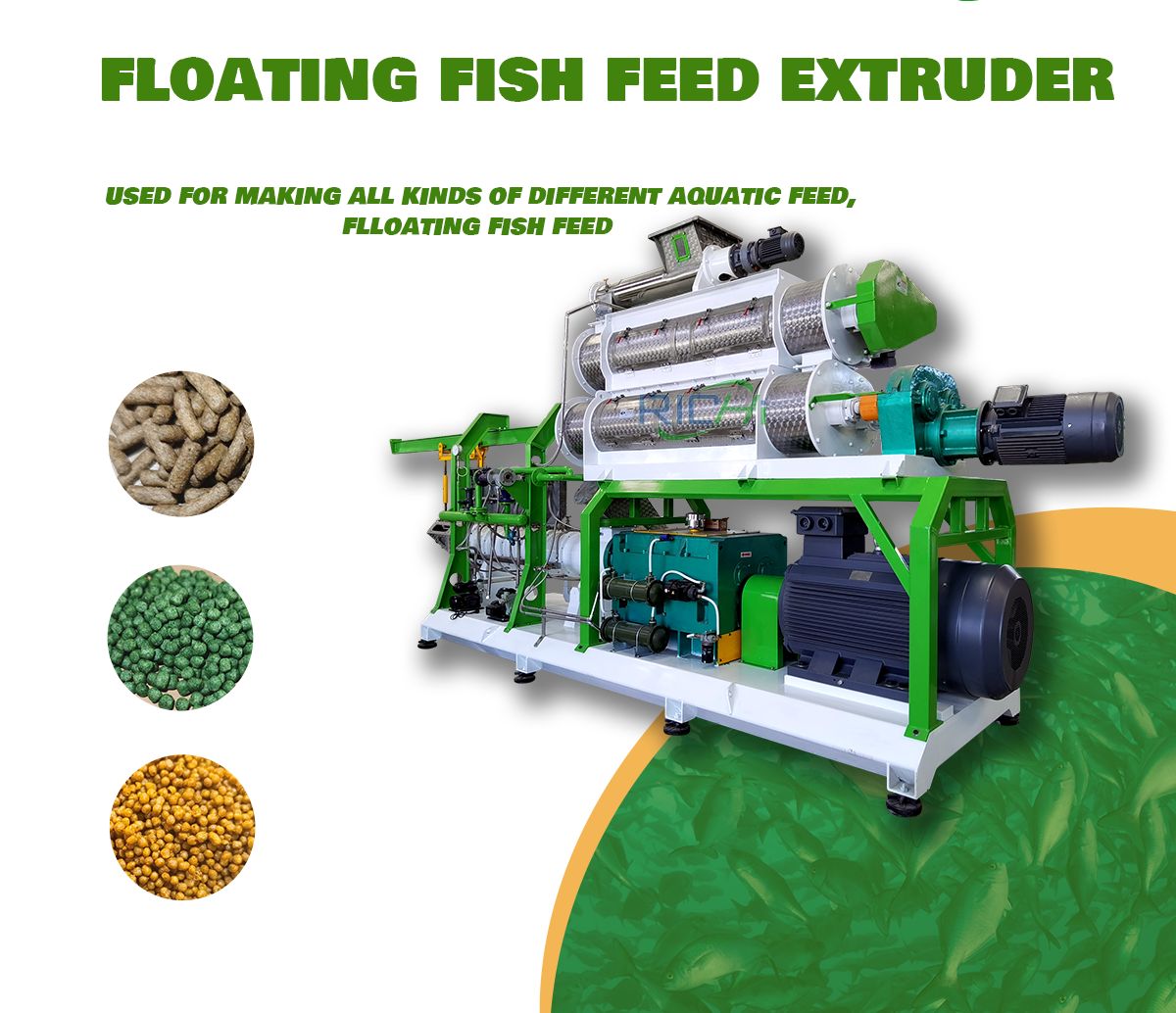

Modern shrimp feed pellet machines incorporate several technological advancements that further enhance their significance in shrimp farming:

- Precision Control Systems: Advanced machines feature computerized control systems that allow for precise adjustment of processing parameters, ensuring consistent pellet quality.

- Energy Efficiency: New-generation machines are designed to be more energy-efficient, reducing operational costs and environmental impact.

- Improved Conditioning: Enhanced conditioning systems ensure better gelatinization of starches and denaturation of proteins, improving feed digestibility.

- Moisture Management: Advanced moisture control features help produce pellets with optimal moisture content, enhancing shelf life and water stability.

- Integration with IoT: Some modern machines can be connected to the Internet of Things (IoT), allowing for remote monitoring and data-driven decision-making.

Supporting Sustainable Aquaculture PracticesAs the aquaculture industry faces increasing pressure to adopt more sustainable practices, shrimp feed pellet machines play a vital role in supporting these efforts:

- Efficient Resource Utilization: By improving FCR and reducing feed waste, these machines help conserve valuable resources.

- Alternative Ingredient Processing: Advanced machines can process a wide range of ingredients, including sustainable alternatives to fishmeal and fish oil.

- Reduced Environmental Footprint: Improved feed quality and water stability contribute to better water quality management and reduced pollution.

- Local Production: Enabling on-site or local feed production reduces transportation needs and associated carbon emissions.

Challenges and ConsiderationsWhile shrimp feed pellet machines offer numerous benefits, there are some challenges and considerations to keep in mind:

- Initial Investment: High-quality machines require a significant upfront investment, which may be challenging for smaller operations.

- Technical Expertise: Proper operation and maintenance of these machines require skilled personnel and ongoing training.

- Feed Formulation Knowledge: To fully leverage the capabilities of these machines, operators need a solid understanding of shrimp nutrition and feed formulation.

- Quality Control: Consistent monitoring and quality control processes are essential to maintain feed quality and machine performance.

Future OutlookThe significance of shrimp feed pellet machines in shrimp farming is likely to grow in the coming years. As the industry continues to expand and face new challenges, these machines will play a crucial role in:

- Meeting increasing demand for high-quality shrimp feed.

- Supporting the development of novel feed formulations, including those with lower environmental impact.

- Enabling more efficient and sustainable shrimp farming practices.

- Facilitating the adoption of precision aquaculture techniques through integration with other technologies.

Conclusion

Shrimp feed pellet machines have become indispensable tools in modern shrimp farming operations. Their ability to produce high-quality, consistent, and customizable feed contributes significantly to improved shrimp growth, farm productivity, and overall sustainability of the industry. As technology continues to advance and the aquaculture sector faces new challenges, the role of these machines in shrimp farming will only become more critical. For shrimp farmers and feed manufacturers looking to enhance their operations and competitiveness, investing in high-quality shrimp feed pellet machines is not just beneficial – it’s becoming increasingly essential for long-term success in the industry.