Here is the detailed case study on the 30T/H animal feed production line written from the perspective of an industry engineer:

Enabling a Robust 30T/H Animal Feed Production Facility

As an experienced engineer in the animal feed industry, I had the opportunity to work closely with a client who recognized the growing demand for livestock products in their region and sought to establish a state-of-the-art 30T/H feed production facility to meet this increasing market need.

The first critical step was to identify a reliable supplier that could deliver a turnkey solution for this high-capacity feed mill. The client thoroughly evaluated several potential partners, placing a strong emphasis on quality, safety, and technological capabilities.

Ensuring the consistent quality and proper dosing of feed ingredients like corn, wheat bran, oilseed meals, and essential vitamins and minerals was of paramount importance, as any lapses in this area could lead to serious animal health issues or reduced production efficiency. The supplier’s ability to implement robust quality control processes was therefore a key selection criterion.

In addition to ingredient quality, the client also closely assessed the suppliers’ technical expertise in areas like optimal particle size control through grinding and homogeneous mixing to prevent ingredient segregation.

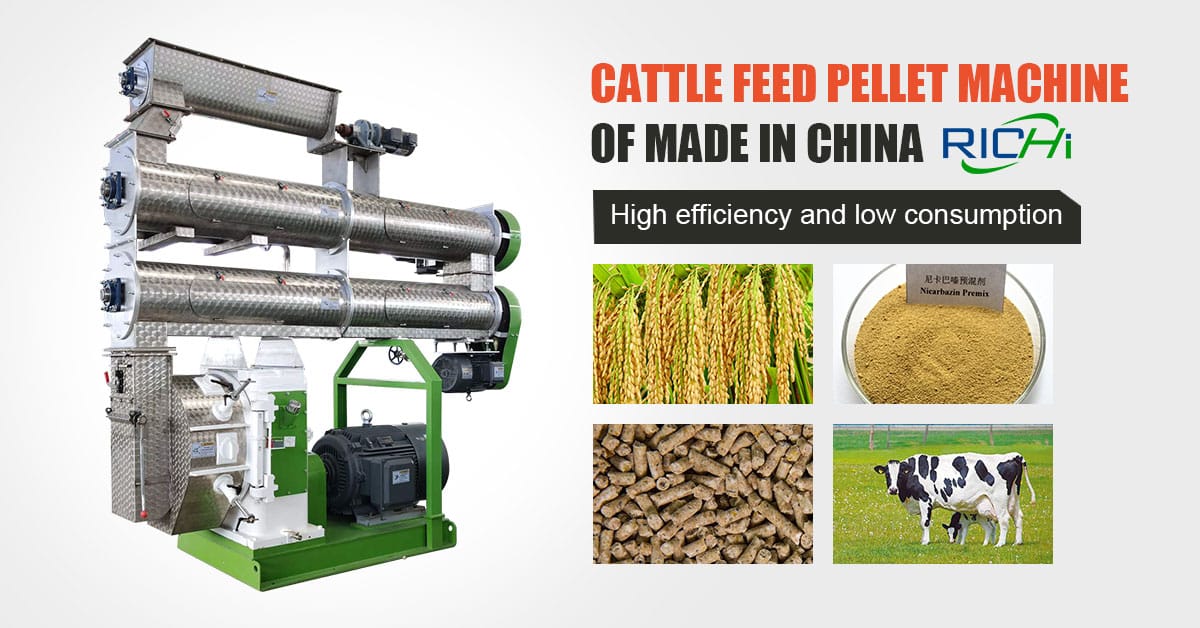

Automation and 24/7 operational capabilities were also important factors, as the client sought to maximize the facility’s cost-efficiency and productivity. After a comprehensive evaluation, the client selected RICHI Machinery as their partner based on their strong technical competencies, quality focus, and competitive pricing.

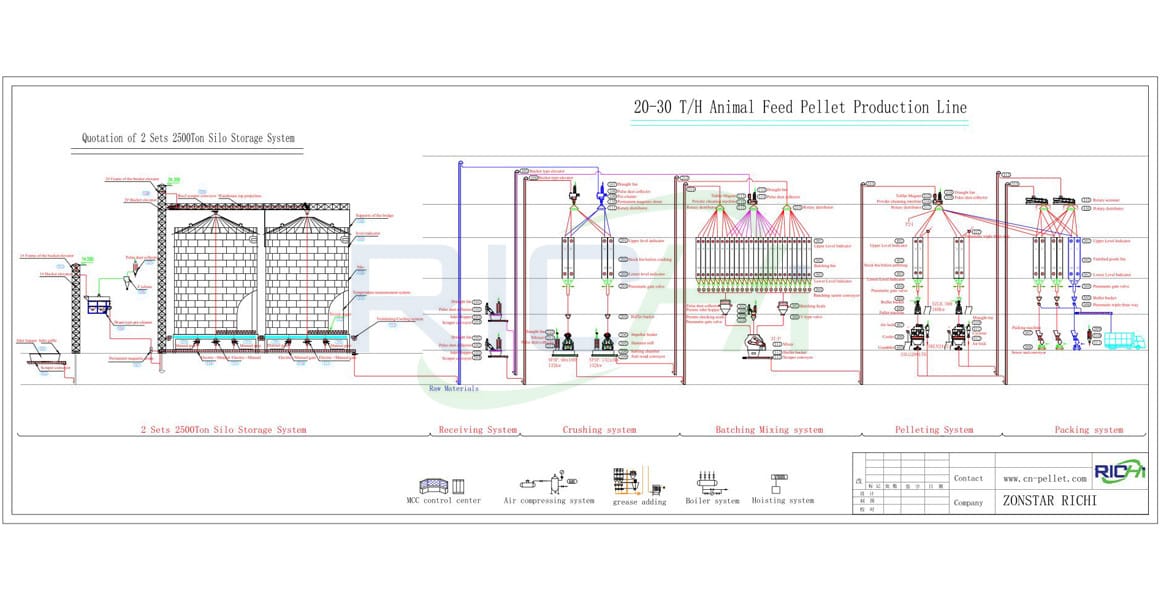

The construction phase of the new 30T/H animal feed production facility presented several practical challenges that required close collaboration with RICHI to overcome. Achieving the target particle size range for the ground ingredients was critical to ensure proper feed intake and digestibility by the animals. The mixer design and operation had to be meticulously tuned to guarantee a consistently homogeneous final product.

Another key issue the client had to address was the lack of adequate storage capacity, which is a common problem in the region. By incorporating sufficient storage silos into the facility’s design, the client was able to buffer against potential supply chain disruptions and maintain uninterrupted feed production.

The reliance on imported feed additives like vitamins and enzymes also posed a vulnerability, prompting the exploration of local and regional sourcing alternatives to enhance the supply chain’s resilience.

Finally, the heavy dependence on road transportation in the country raised concerns about potential logistical disruptions. By strategically locating the production facility and leveraging alternative modes like rail where feasible, the client was able to mitigate this risk and ensure reliable feed deliveries to their customers.

Through this collaborative effort with RICHI Machinery, the client successfully commissioned their new 30T/H animal feed production line, equipped with the necessary quality controls, technological capabilities, and supply chain resilience to meet the growing demand for high-quality, cost-effective livestock feed in the region.

This achievement positions the client’s business for long-term success in the rapidly expanding animal agriculture market.